The Single Strategy To Use For Roar Solutions

The Single Strategy To Use For Roar Solutions

Blog Article

About Roar Solutions

Table of ContentsRoar Solutions Can Be Fun For AnyoneThe 45-Second Trick For Roar SolutionsRoar Solutions Can Be Fun For Everyone

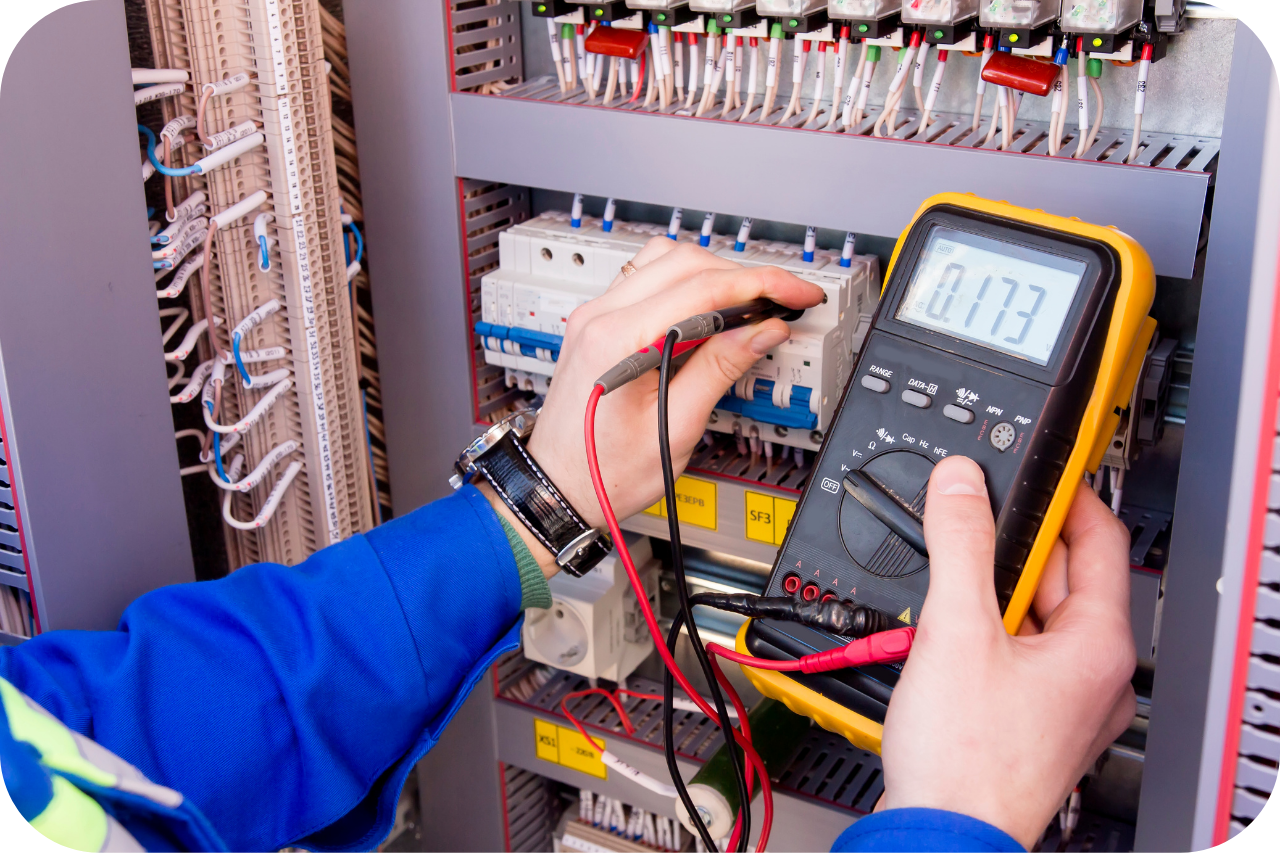

In order to shield installments from a prospective explosion an approach of evaluating and categorizing a potentially hazardous area is called for. The function of this is to make certain the correct selection and setup of equipment to inevitably stop a surge and to guarantee security of life.

(https://www.artstation.com/roarsolutions6/profile)

No tools should be set up where the surface temperature level of the tools is above the ignition temperature of the provided hazard. Below are some common dust dangerous and their minimum ignition temperature level. Coal Dust 380C 225C Polythene 420C (thaws) Methyl Cellulose 420C 320C Starch 460C 435C Flour 490C 340C Sugar 490C 460C Grain Dirt 510C 300C Phenolic Material 530C > 450C Aluminium 590C > 450C PVC 700C > 450C Soot 810C 570C The chance of the hazard existing in a focus high adequate to create an ignition will differ from place to place.

Unsafe location electric tools possibly made for usage in greater ambient temperature levels. Area Repair Service By Authorised Employee: Difficult screening may not be needed nevertheless certain procedures may need to be followed in order for the tools to maintain its third event ranking. Each item of tools with an unsafe score need to be examined separately.

5 Simple Techniques For Roar Solutions

The tools register is a comprehensive data source of tools records that includes a minimum collection of areas to determine each thing's place, technical parameters, Ex classification, age, and ecological information. The ratio of Thorough to Shut inspections will be determined by the Tools Risk, which is evaluated based on ignition threat (the likelihood of a source of ignition versus the probability of a flammable ambience )and the hazardous area classification

( Zone 0, 1, or 2). Applying a robust Risk-Based Evaluation( RBI )method is critical for ensuring conformity and safety and security in handling Electrical Tools in Hazardous Areas( EEHA).

Getting My Roar Solutions To Work

In terms of explosive threat, a harmful location is an atmosphere in which an explosive environment is existing (or might be expected to be existing) in amounts that call for unique safety measures for the building, installation and use tools. hazardous area electrical course. In this post we discover the challenges encountered in the work environment, the danger control procedures, and the required competencies to function securely

These substances can, in certain problems, form eruptive ambiences and these can have significant and unfortunate repercussions. Many of us are acquainted with the fire triangle remove any type of one of the three components and the fire can not happen, but what does this mean in the context of hazardous locations?

In many circumstances, we can do little concerning the degrees of oxygen in the air, yet we can have significant impact on sources of ignition, for instance electric equipment. Unsafe areas are documented on the unsafe area classification illustration and are recognized on-site by the triangular "EX" sign. Right here, among various other essential information, zones are divided into basics 3 kinds depending upon the threat, the chance and duration that an eruptive atmosphere will exist; Area 0 or 20 is deemed the most harmful and Zone 2 or 22 is deemed the least.

Report this page